Vision laser replaces wire erosion in tool manufacturing

29.10.2025

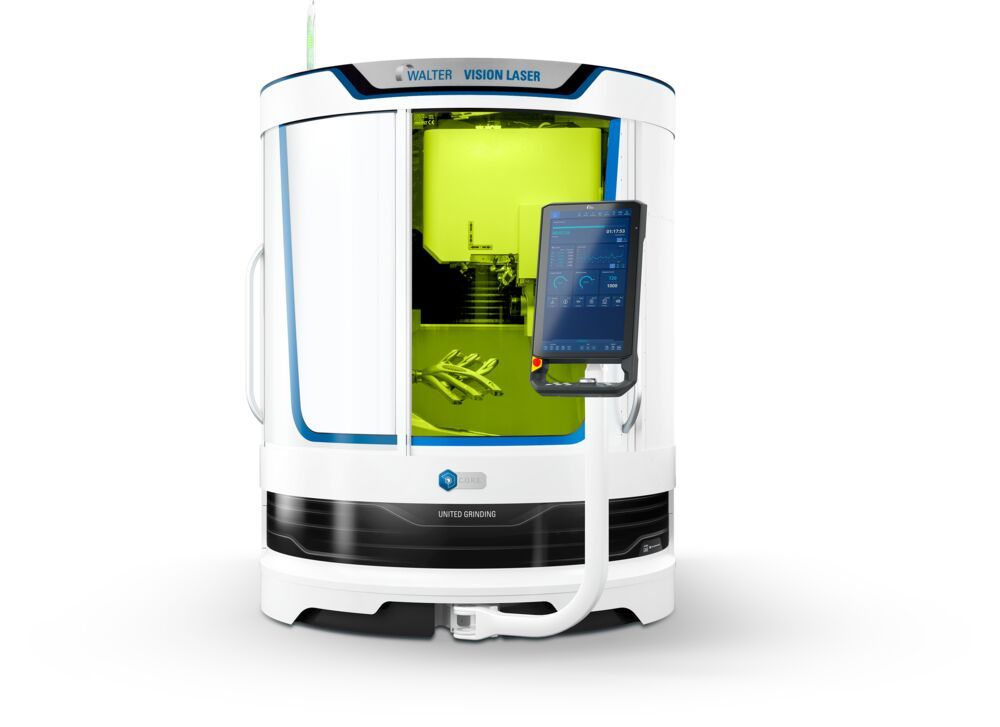

With the Vision Laser, Walter introduces a high-performance alternative to wire erosion — offering faster processing, finer surfaces, and greater flexibility for complex tool geometries.

Photo: Vision Laser machine with Robot Loader 25.

Vir: Walter Maschinenbau

The latest Vision Laser laser processing machine from Walter Maschinenbau offers innovative laser technology for a wide range of applications for brazed tools in modern tool production. The design of the machine is based on the Helitronic Vision, which has been tried and tested and reliable for decades. The laser technology used offers industry-proven reliability for the precise and efficient laser processing of tools with high quality requirements.

Photo: Live process cameras in the Vision Laser.

Vir: Walter Maschinenbau

The Vision Laser enables efficient, contact-free processing of a variety of tool materials, including PCD (polycrystalline diamond), CVD (chemically deposited diamond), MKD (monocrystalline diamond), and carbide. It is ideal for applications such as end mills, ball nose end mills, step tools and more. The Vision Laser ensures chipping- and crack-free cutting edges across a wide grit range, boosting performance and wear resistance. Even highly complex geometries — such as chip breakers and concave internal contours — can be produced with maximum accuracy. The process is resource-efficient, as it eliminates the need for consumables like cooling lubricants, filters or wires.

Photo: Automatic calibration unit for the Vision Laser.

Vir: Walter Maschinenbau

Traditionally, wire erosion has been the go-to method for manufacturing brazed PCD tools. However, it involves material consumption and comes with limitations in terms of achievable geometries and risk of grain breakage. The Vision Laser overcomes these drawbacks with several key advantages. It enables complete production in a single clamping operation — from raw blank to finished tool, including integrated chip breakers — while offering cutting speeds up to twice as fast as wire erosion for comparable materials. Since it is independent of material hardness and electrical properties, it allows seamless processing of even the hardest composites. Additionally, the system achieves exceptional surface quality with minimal roughness values, making it ideal for high-performance tools.

Photo: Examples of tools that can be manufactured with the Vision Laser.

Vir: Walter Maschinenbau

The Vision Laser is equipped with GTR Profdia Laser software, a classic application that closely resembles the widely used GTR Profdia Erosion. This ensures a smooth transition for users already familiar with wire EDM technologies.

At the core of the system lies Walter’s advanced operating platform, Core — one of the most modern machine operating systems available today. All functions, from calibration to warm-up, are handled via Core, ensuring a unified and efficient user experience. Features such as automatic axis calibration, laser focus adjustment, and turning centre alignment simplify operation while enhancing precision and productivity. Sustainability is built in through continuous monitoring of air and energy consumption, as well as laser and temperature data.

Photo: View of the software on the core panel.

Vir: Walter Maschinenbau

Optional process monitoring includes up to three live cameras for calibrating blanks and visualising machining progress either in split view or full screen. In addition, the proven Walter Robot Loader 25 — capable of handling up to 70 HSK tools — is fully integrated into the Core operating system, further streamlining automated tool handling.

Objavljeno na: www.etmm-online.com

Več informacij na: www.walter-machines.com