LS Mtron Introduces the ONE* MuCell Product Line – a ‘One Stop Solution’ for Foam Molding

17.12.2021

LS Mtron has introduced a new line of injection molding machines, each equipped with Trexel MuCell technology for foam molding applications.

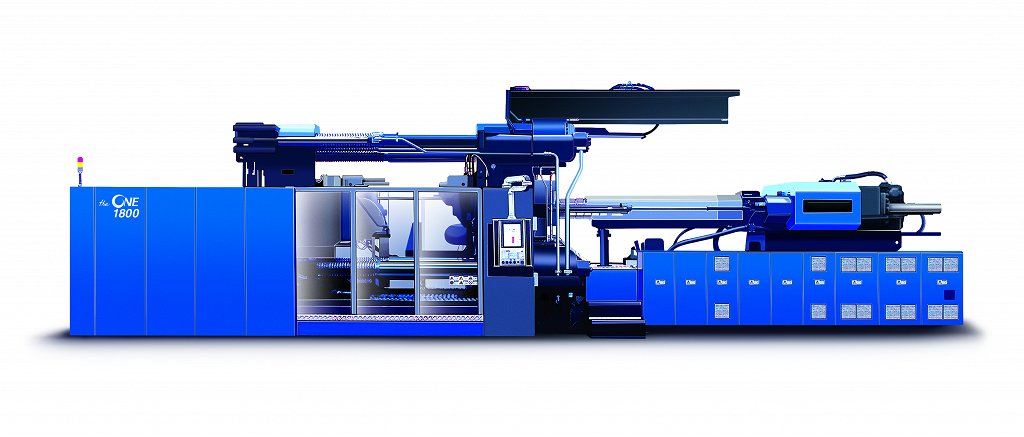

The ONE 1800. Photo: LS Mtron

The ONE 1800. Photo: LS Mtron

The ONE* MuCell® product line of injection molding machines consists of 10 models (from 500~3,300 tons), with features that will help molders succeed with foam molding for a wide variety of applications. Key features include the Core Back function, which stabilizes and maximizes the foaming rates of a product, and the Servo Valve, which allows for precise position control.

For more details on the advanced features of the ONE* MuCell® machines, see Table 1.

<Table 1> Key Features of the ONE* MuCell®

| Classification | Features |

| U-shaped tie bar teeth | -Higher tie bar strength -Improved half nut tightening |

| Half nut – Simultaneous operation | -Reduced cycle time |

| Tie bar spacing construction(opt) | -Easy to change molds in low ceilings |

| Digital position sensor | -Precise position control -Reduced errors |

| KEBA Controller | -Precision control -Enhanced user convenience |

| Screw design only for MuCell® foaming | -L/D:23 (MMU:22) -Ball Check Valve with backflow protection |

| High-pressure system | -Reduced cycle time |

| Injection unit optimized for foam molding | -High floor area ratio and injection speed -Accurate back pressure control |

LS Mtron provides its 'One Stop Solution’ for foam molding in various applications, ranging from molds and auxiliary equipment to complete turnkey machines. These turnkey packages will provide improved yield by offering customers the optimized conditions for foam molding based on LS Mtron's accumulated know-how and experience.

LS Mtron and Trexel Agreement

LS Mtron, the largest manufacturer of injection molding machines from South Korea, signed its agreement with Trexel to license Trexel's MuCellâ technology in 2019.

“MuCell is an outstanding technology that satisfies both light-weighting and quality of plastic products, and will contribute to customer productivity improvement and cost reduction," said Seung-Dong Park, head of LS Mtron’s Injection Research Center. “We are pleased to now be introducing this new line of MuCell-capable molding machines to the plastics industry.”

CTO Kyung-Nyung Woo, head of LS Mtron’s Technology Development Division, said, "Through this agreement with Trexel, we will cooperate not only for current Micro cell technology but also for future Nano cell technology development to continuously strengthen lightweight technology."

■ Inquiry: LS Mtron's Molding Machine Division’s Website www.lsinjection.com