DOMINO Project: Impulses for modern mouldmaking

06.10.2025

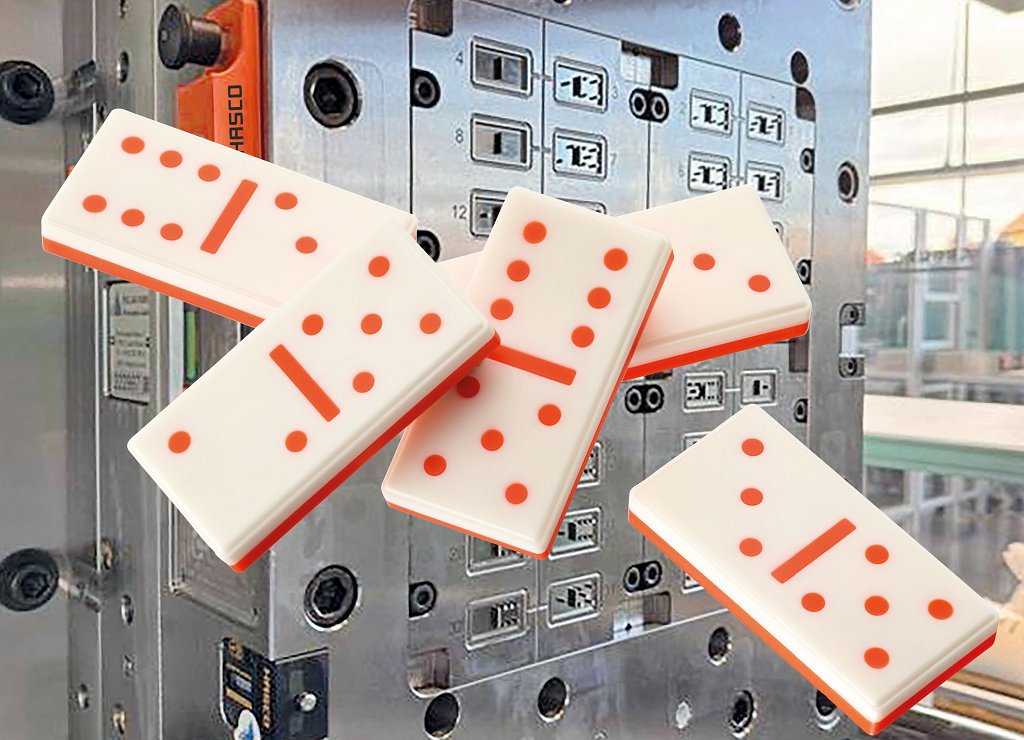

Mouldmakers are under heavy innovation pressure nowadays – what is needed are precise, economical and, at the same time, flexible solutions. With the joint DOMINO project, the partner companies HASCO, ARBURG and POLAR-FORM demonstrate how genuine added value can be created for practical application through new mould concepts.

Photo: DOMINO Project

Innovative 3D-printed mould concept

Instead of opting for established solutions such as cube moulds or rotary tables, DOMINO pursues the aim of enabling in-situ injection moulding of numerous 2-component parts within one compact family mould, with the help of a 3D-printed hot runner system. The concept opens up completely new design freedoms for part designers, end customers and mouldmakers alike.

Focus on customer benefits

DOMINO shows how technological creativity and cooperative partnerships can shift technical boundaries. Users benefit from noticeable advantages: reduced cycle times, the use of smaller machines, reduced space requirements and, overall, more economical production. At the same time, the project offers valuable ideas for future mould developments and illustrates the potential of 3D printing for modern mouldmaking.

Driving force for the industry

As an innovation driver for the entire industry, DOMINO sees itself less as an individual project, and more as an example of how forward-looking planning, innovative technology and industry know-how are intertwined. This results in solutions that are not only technically convincing but also make a sustainable contribution to competitiveness.

Visitors to K 2025 can experience the DOMINO project live at the ARBURG stand (hall/stand 13/A13) and be inspired by the innovative ideas for mouldmaking.

Source: HASCO