Developing Next Generation Manufacturing with \"Uniqueness and Creativity\" Japan MST Corporation

07.05.2025

MST Corporation has a history of 88 years, which is longer than any other tool holder manufacturer in Japan. While people at the age of 88 are entitled to celebrate their longevity, the company's business strategy is still youthful. A new plant was constructed adjacent to its existing plant in the spring of 2014. MST is actively introducing systems for unattended operation over extended periods to strengthen its commitment to "next generation manufacturing." The company is also devoting itself to the establishment of a system to focus on the global market.

Fits comfortably in your hand ― Mr. Haruki Mizoguchi, President of MST Corporation, asserts that this is anessential condition for tool holders, the core product of the company. "As tool holders connect machines and tools, it is inevitable that they are handled by people. It is therefore most important that they are light and have a simple mechanism," says the president. The company was founded as "Mizoguchi Iron Works & Co., Ltd" in 1937 to manufacture industrial machinery and machine tools in Nogata, Fukuoka Prefecture (southern Japan), and started to produce tool holders for machine tools in 1946. After its move to Nara Prefecture in 1965, the name was changed to the current one in 1991. MST Corporation has pursued original technologies according to the corporate philosophy of "uniqueness and creativity" since its foundation. One of the achievements of this pursuit is the shrink-fit holder Slim Line that is the representative product of the company. Slim Line was originally developed to respond to rapid improvements in the speed and accuracy of machining centers. In the development process, MST focused on a chucking method in anticipation of further improvements in speed and accuracy in the future, instead of sticking to the tapered collet method, which was a specialty of the company. By doing so, MST selected the way toward technological innovation in line with its "uniqueness and creativity" policy.

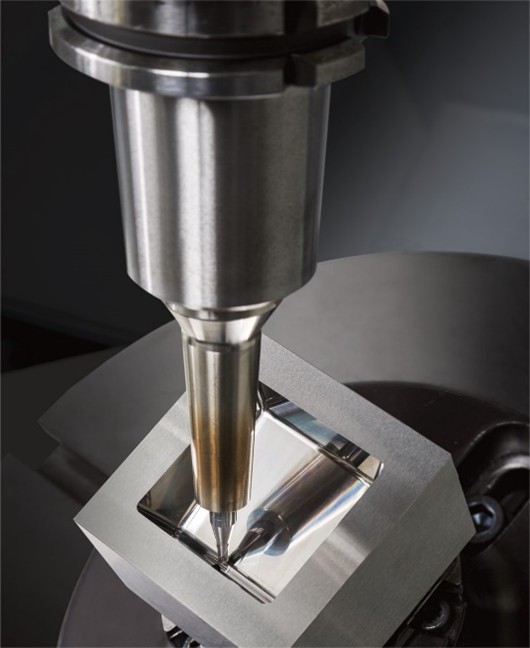

Photo: Mirror surface machinning

Adoption of HSK Spindle Further Promoted Relations between the Two Companies

Shrink-fit based on thermal expansion and shrinkage of metal was not a totally new technique. Nonetheless, MST Corporation had original development technologies and expertise as it had been interested in the technique. Slim Line was put into the market in 1998, and is now widespread in manufacturing facilities as an essential high-accuracy holder for precise processing. The production of Slim Line tool holders involves many Mazak machines. In addition to the 12 units previously installed in the new plant, an INTEGREX i-200S, INTEGREX i-300ST and VERTICAL CENTER NEXUS 535C-II have been delivered to MST recently. The company began to introduce Mazak machines much more often when Mazak participated in the planning and consideration of the ICTM standards for HSK for multi-tasking machines, in which MST corporation was involved as a leading company. The business relationship between MST and Mazak was deepened further when the HSK milling spindle was made available for the INTEGREX series, our flagship multi-tasking machine. The INTEGREX series has helped MST reduce the processing time and increase production, and also made it possible to perform unattended operation over extended periods by integrating the machines with robots.

Photo: Many Mazak machines contribute to high-accuracy processing

Mazak Machines are expected to Contribute to the Operation of the Unattended Factory

The new plant aims to achieve cost reduction, delivery in a shorter period of time and next generation manufacturing in an improved environment. To meet these targets, it is promoting (1) operation of an unattended factory based on a unique automatic transfer system, (2) improvement of material handling through a review of the production system (classified by process instead of product) and (3) pursuit of better quality through improvement of the environment in the plant. Mazak's multi-tasking machines and systems, which are effective for process integration, are expected to make great contributions as the main equipment in the unattended factory. MST Corporation plans to raise the ratio of overseas sales from the current level of 35% to 50% with the increase of its production capacity as a result of the full-scale operation of the new plant. Its overseas inventory centers "J-compo" have been established in the United States, Germany, Hong Kong and Singapore. The focus on the global market is shared by Mazak's business strategy. The bond created through multi-tasking machines is as rigid as the two-face HSK contact system.

Photo: Automated Integrex system with AGV

Source: Mazak