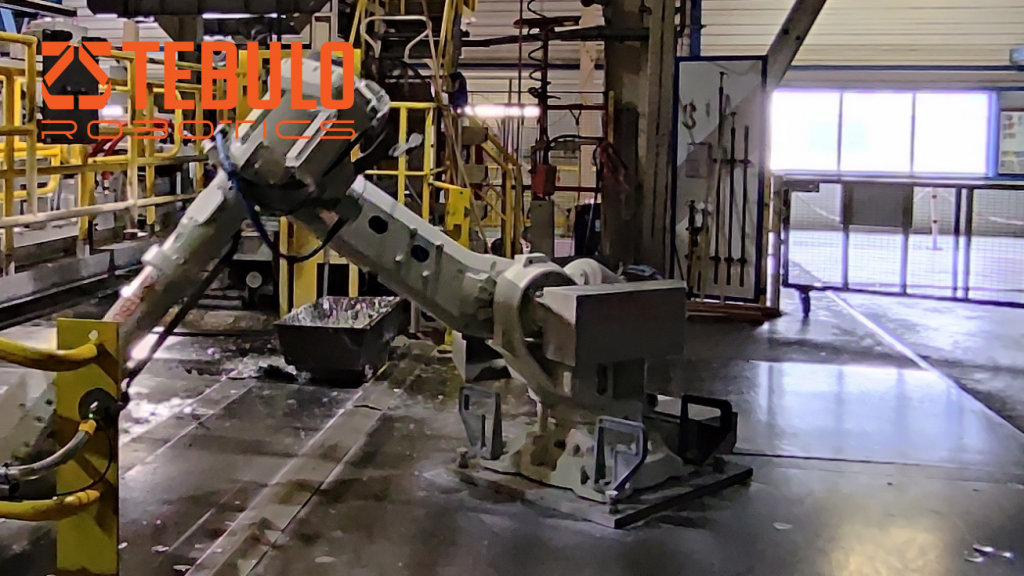

Tebulo Robotics presents at METEC 2023: Innovative dross-robot solution

09.06.2023

At METEC 2023, Tebulo Robotics presents a user-friendly dross-robot system with smart properties, which may easily be integrated within any existing hot-dip galvanizing process. Even when space is limited. This allows for a substantial safety improvement in the operators’ working environment.

This robot system hardly requires human interference. The above-mentioned ‘out of the box’ solution consists of a combination of a front robot and a V-side robot in conjunction with smart and user-friendly control software and a patented tool changer. The V-side robot moves with various tools back and forth on a track over the hot dip galvanising bath while closely cooperating with the front robot. By means of two kinds of rakes, this robot delivers the dross from the rear-side of the steel plate in a controlled manner in the work area of the front robot. The last-mentioned robot takes over the dross and makes sure that it is disposed of via the front side. Just as the V-side robot, the front side robot possesses an in-house developed and patented tool changer, containing rakes and scoops in various designs. In close consultation with the customer, Tebulo Robotics supplies tools tailored to the project requirements in order to provide an optimal dross process at all times. Tool stations with separate rakes and/or scoops and the robot-actuated tool changer, with an ingenious connecting system mounted on the robot's wrist, may be deployed trouble-free with a 500°C hot dip bath, since they were specially designed for heavy-duty applications such as these. By means of the robust tool changer, the robot itself picks the correct tools, returns these and stores them in the tool station, which is always situated within the robot's working area. As soon as the robot picks up a tool, it is mechanically locked in place followed by a verification measurement in order to determine whether the dimensions of the chosen tool are acceptable, prior to starting the cycle. After deployment, the tool is put back and unlocked. Since every tool has an individually shaped pick-up point, when they are returned, the tools cannot be hung in the wrong spot by the operator (poka yoke). Perhaps superfluously, it is interesting to mention that this robot may also be used for other types of work, such as environmental cleaning, moving safety fences or taking zinc samples. From the factory, Tebulo Robotics provides 1 control programme for each zinc pot. This may be expanded upon demand. Via the user-friendly HMI, control can easily be optimised per zinc pot, or a cycle of your choice may be manually designed. This innovative and superior robot makes the industrial processes therefore not only remarkably safer, but also more productive and sustainable.

* Tebulo Robotics is a leading player, specialising in design, construction and delivery of innovative, technically high-quality robot integrations for a wide variety of applications, ranging from design to commissioning.

Stand Number: G20, Hall 4

For more information, please visit: www.tebulorobotics.com