Top form with surface know-how

28.03.2022

In the multifaceted area of forming tools, Oerlikon Balzers offers tailor-made surface solutions coupled with application competence.

Lightweight construction, high-strength materials, complex components – the trends in metal forming, aluminium die casting and plastics processing demand the utmost in tool performance as well as customized solutions for each process environment and the specified goals. The coatings expert, Oerlikon Balzers, regards every customer enquiry as an individual case – and provides application-specific consulting together with a recommendation for suitable surface treatments from the BALINIT® and BALITHERM® range for forming tools. The hard facts on the bottom line are: greater efficiency and productivity, lower maintenance and costs.

The services offered by Oerlikon Balzers comprise application-specific consulting together with a recommendation for suitable surface treatments from the BALINIT® and BALITHERM® range for forming tools. (Graphic: Oerlikon Balzers)

The services offered by Oerlikon Balzers comprise application-specific consulting together with a recommendation for suitable surface treatments from the BALINIT® and BALITHERM® range for forming tools. (Graphic: Oerlikon Balzers)

Metal forming: The example of AHSS

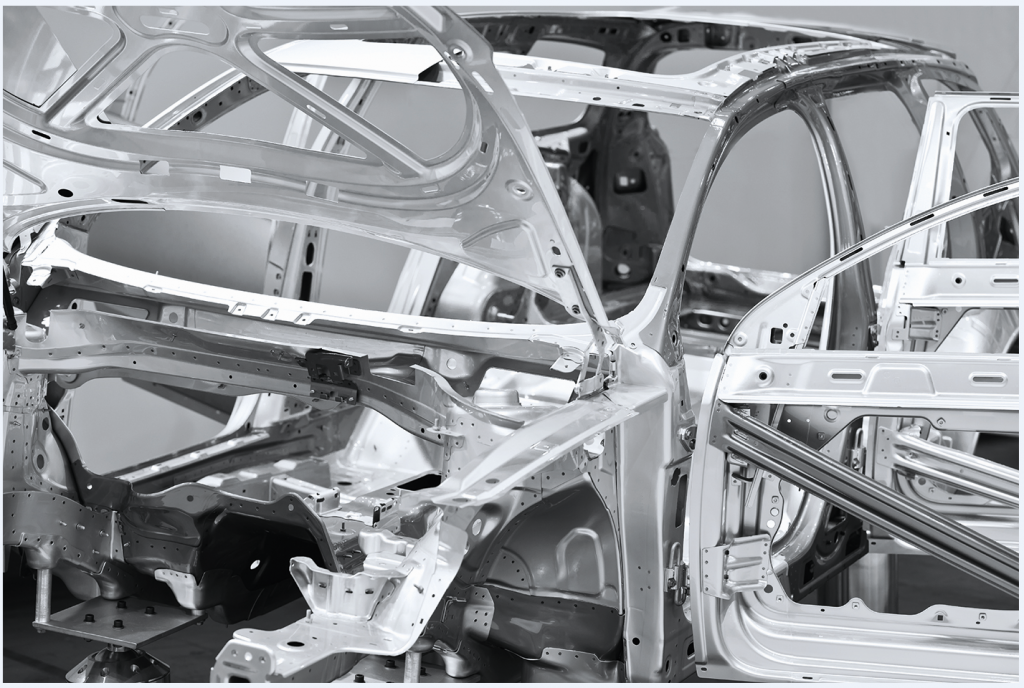

Automobile manufacturing highlights the primary challenges faced in metal forming: Emissions constraints and improved passenger safety require ever lighter yet also more stable vehicles. The proportion of high-strength steel (Advanced High Strength Steel - AHSS) per car is projected by Ducker Worldwide market researchers to rise from 68 kg in 2009 to 204 kg in 2020. This, in turn, demands optimized surface solutions for tools which will increasingly be subject to abrasive and adhesive wear in AHSS forming and will also experience greater loading at certain locations, such as radii or drawing rods. Ultimately, the results of this include more scrap and more downtime.

The proportion of high-strength steel (AHSS) per car is projected by Ducker Worldwide market researchers to rise from 68 kg in 2009 to 204 kg in 2020. (Image: iStock)

The proportion of high-strength steel (AHSS) per car is projected by Ducker Worldwide market researchers to rise from 68 kg in 2009 to 204 kg in 2020. (Image: iStock)

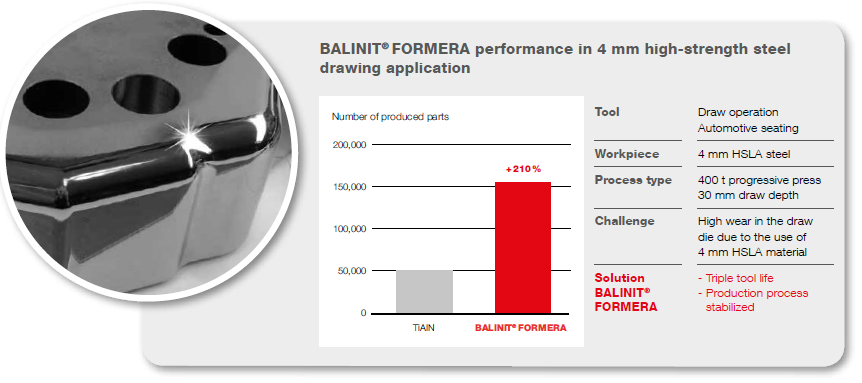

BALINIT® FORMERA has been developed by Oerlikon Balzers specially for tasks such as these. The tool coating based on CrAlN delivers significantly improved abrasive wear resistance and coating adhesion for deep drawing or flanging of AHSS sheet materials at pressures in excess of 500 Mpa than do current products on the market. For example, in deep drawing of 4 mm thick HSLA steel for metal parts in automobile seats, BALINIT® FORMERA yielded a sixfold increase in tool service life compared to a common competitor’s product and also stabilized the production process as well.

Persuasive results for deep drawing of HSLA steel (Graphic: Oerlikon Balzers)

Persuasive results for deep drawing of HSLA steel (Graphic: Oerlikon Balzers)

In order to achieve results such as these and to design new coating systems with this kind of high-level performance in actual operation, Oerlikon Balzers works together with the forming industry as well as with partner institutes. Tests at the premises of selected customers were of decisive importance for the refinement of BALINIT® FORMERA to make it a solution with the best performance for AHSS applications under actual industrial production conditions.

Other coating solutions for metal forming have also demonstrated the convincing results of this approach: A forming tool for the fabrication of stainless steel exhaust system shields was coated with BALINIT® ALCRONA PRO and BALINIT® C. This combination unites high hardness with very good friction values and improves the tool life by tenfold as compared to the untreated tool, which saves up to 86 percent in production costs.

“Before selecting a suitable treatment, we consider the tool, including its size, geometry, base material and its hardness, the forming process and application temperature as well as the use of lubricants, in addition to further application parameters. Depending on the case, we also recommend special pretreatments to improve the supporting effect for the tool surface. Ultimately, many factors determine the final decision,” explains Phil Read, Market Segment Manager for Metal Forming at Oerlikon Balzers, commenting on this fundamental procedure.

Aluminium die casting: Process know-how in demand

Working with aluminium die casting also requires an understanding of the complete casting process so that beneficial adaptations can be made to the surface solutions. For example, aluminium soldering can form on the tool, which can complicate demoulding and ultimately cause component deformation as well as increase the scrap rate. These problems are exacerbated by parts with complex geometries, for example, for the engine compartment, gear box or structure of an automobile. One reason for this is the increasing trend towards designing one part from multiple parts to further reduce space requirements and weight in the vehicle. Particularly part designs with tight ribbing give rise to demoulding problems and substantial maintenance work.

In cases such as these, Oerlikon Balzers has achieved very good results with BALINIT® LUMENA, BALINIT® FORMERA and BALINIT® ALCRONA PRO.

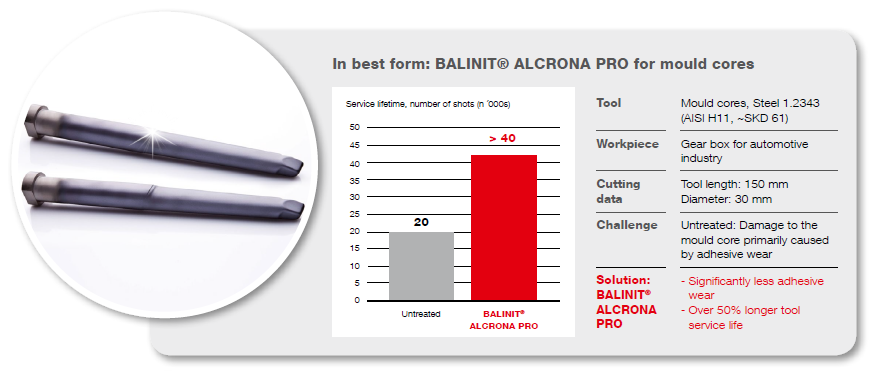

These PVD (Physical Vapour Deposition) coatings are effective against erosion and abrasion, against soldering of the Ti rod, and against oxidation and alloying. BALINIT® ALCRONA PRO plays out its advantages exceptionally well in mould cores: In serial production of gear box housings, the AlCrN-based coating lowers the adhesive wear significantly and increases tool life by 50 percent as compared to untreated cores.

In top form: BALINIT® ALCRONA PRO for mould cores (Graphic: Oerlikon Balzers)

In top form: BALINIT® ALCRONA PRO for mould cores (Graphic: Oerlikon Balzers)

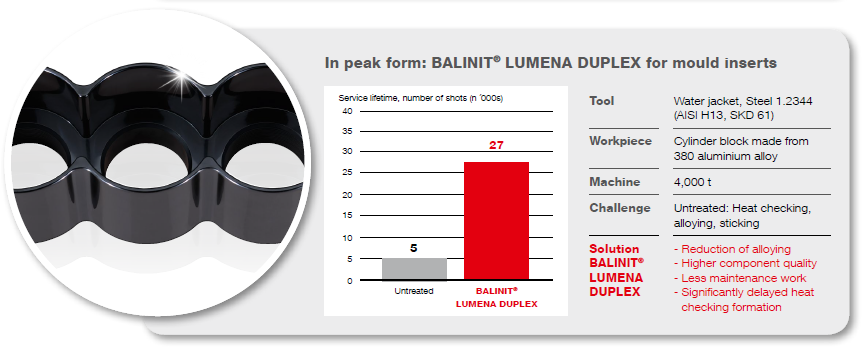

The combination of pretreatment of the tool surface and subsequent PVD coating has proven itself not only in metal forming, but also in aluminium die casting. The BALINIT® ADVANCED series, for example, employs a diffusion process and the BALINIT® DUPLEX series makes use of nitriding as a pretreatment. This results in advantages such as higher surface hardness and hot hardness as well as compressive strength. For serial applications in mould inserts, BALINIT® LUMENA DUPLEX has been able to solve problems such as fire cracking, alloying and soldering as well as to increase the tool life quantity by more than fivefold as compared to the uncoated moulds for die casting cylinder blocks made of an aluminium alloy. "With our current understanding of the process and our surface finishing expertise, it is possible to achieve similar solutions and results in virtually all cases," says Thomas Vermland, Segment Manager for Forming Tools at Oerlikon Balzers.

In great shape: BALINIT® LUMENA DUPLEX for mould inserts (Graphic: Oerlikon Balzers)

In great shape: BALINIT® LUMENA DUPLEX for mould inserts (Graphic: Oerlikon Balzers)

The exceptionally hard, extremely erosion and wear-resistant coatings from Oerlikon Balzers are a significant factor when it comes to protecting the mould from soldering and premature fire cracks. BALINIT® FORMERA plays a major role in stabilising the casting process and in reducing both maintenance costs and waste material.

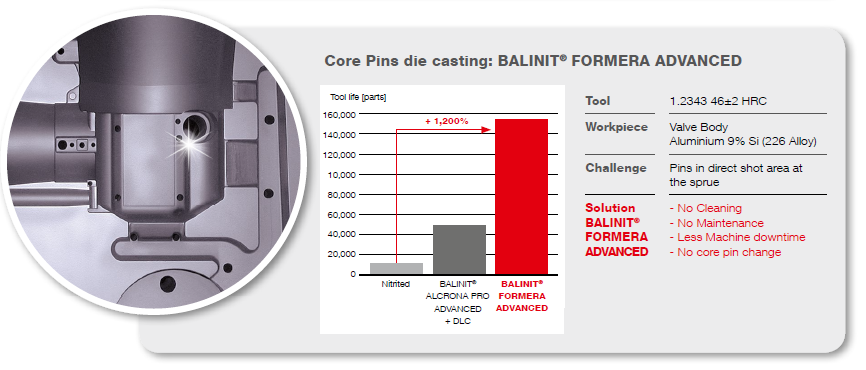

In great shape: BALINIT® FORMERA for mould core pins (Graphic: Oerlikon Balzers)

In great shape: BALINIT® FORMERA for mould core pins (Graphic: Oerlikon Balzers)

Wide variety of solutions for injection moulding, extrusion, etc.

In the area of plastics processing as well, with its vast array of applications, materials and challenges, it pays to look at each case individually. If the task at hand is the injection moulding of sensitive plastic parts with a high-gloss surface, both the surface finish of the tool and the demoulding process itself are of very great importance. Scratches on the mould are a direct cause of scrap and remedying these costs time and money. The thermoplastics, with their varying pigmentation depending on the colour, influence processing and demoulding in a number of ways. Moreover, the use of glass-fibre reinforced plastics increases tool wear. Against this background and in light of the great effort required for quality assurance, production is always looking for opportunities to improve their efficiency and save on costs.

Oerlikon Balzers has a solution for this which satisfies many demands simultaneously: BALITHERM® PRIMEFORM. In this plasma-assisted process, a hard diffusion layer is created in the surface of the mould itself. Not only does the tool become more scratch resistant and impervious to corrosion and aggressive substances, it can also be polished to a high gloss, welded or etched – with no need for a plasma re-treatment. Above all, the flow behaviour of the injected plastic and the demouldability are improved so that shorter cycle times become possible. This package of advantages has demonstrated remarkable results after treatment of tools for the fabrication of instrument panels in automobile manufacturing: Scrap and maintenance costs go down while productivity goes up by 30 percent.

Results like these can also be attained in other industry sectors: BALITHERM® PRIMEFORM can be employed in consumer, electrical or medical technology, as well as for plastics in furnishings or packaging. Even large-format tools of up to 40 tonnes in weight, 9.5 metres in length and 3 metres wide can be treated. Upon request, it is also possible to reduce the application temperature from 480 to 380 degrees Celsius, which means that commercially available tool steels with a low tempering temperature are treatable.

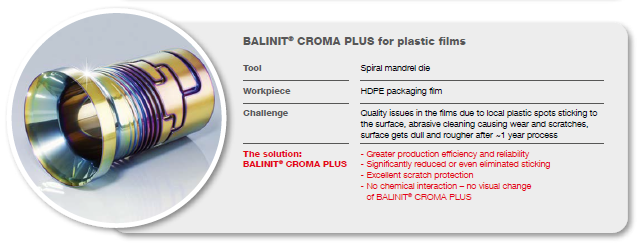

A further field of application for solutions from Oerlikon Balzers is that of extrusion. Particularly in the area of film extrusion as well as rubber processing, two CrN coating variants have proven themselves: BALINIT® CROMA and BALINIT® CROMA PLUS. These multiple-layer coatings offer protection against abrasive wear and sticking and they improve the slip behavior as well as the flow of plastics such as PA or ABS. Thus, no wear was evident in practice on extruder screws treated in this way even several years after the coating was applied. On spiral mandrel dies for manufacturing films, deposit formation was reduced and tool lifetimes were increased tenfold. Large tools such as screws or sheet dies with a length of up to 4.5 metres, or spiral mandrel dies with a diameter of 1.4 metres can also easily be coated.

BALINIT® CROMA PLUS delivers impressive results in the production of plastic films with spiral mandrel dies (Graphic: Oerlikon Balzers)

BALINIT® CROMA PLUS delivers impressive results in the production of plastic films with spiral mandrel dies (Graphic: Oerlikon Balzers)

When moving mould parts are involved, such as sliders and ejectors, or lubricant-free running, the exceptionally smooth DLC (Diamond-Like Carbon) coatings are a perfect match for the job. The silicon-doped DLC coating, BALINIT® DYLYN, for instance, delivers high wear and corrosion protection as well as outstanding friction and anti-stick properties. It reduces deposit formation, eliminates burner streaks, improves the flow behaviour of the plastic melt and thus increases the delivery rate. Using this coating solution for sliders and mould cores, a pharmaceutical packaging manufacturer was able to shorten cycle times by about 20 percent in the fabrication of plastic dosing aids while increasing the service life and the production reliability and at the same time reducing maintenance costs.

What’s more, BALINIT® DYLYN has proven to be one of the few products suitable for coating copper-beryllium mould cores, which have a tempering temperature of only 300 degrees Celsius.

The product can also be combined with BALITHERM® PRIMEFORM, which improves properties such as protection against corrosion, abrasion, scratches and sticking even more. “This is a further example of the flexibility we have in combining the advantages of our broad range of surface solutions for plastics processing tools – all in the interest of higher productivity and quality as well as time and cost savings. The basis for this is always meticulous analysis of the situation and close cooperation with the customer,” sums up Thomas Vermland, Segment Manager for Forming Tools at Oerlikon Balzers.

For more information, please visit: www.oerlikon.com/balzers/at/en