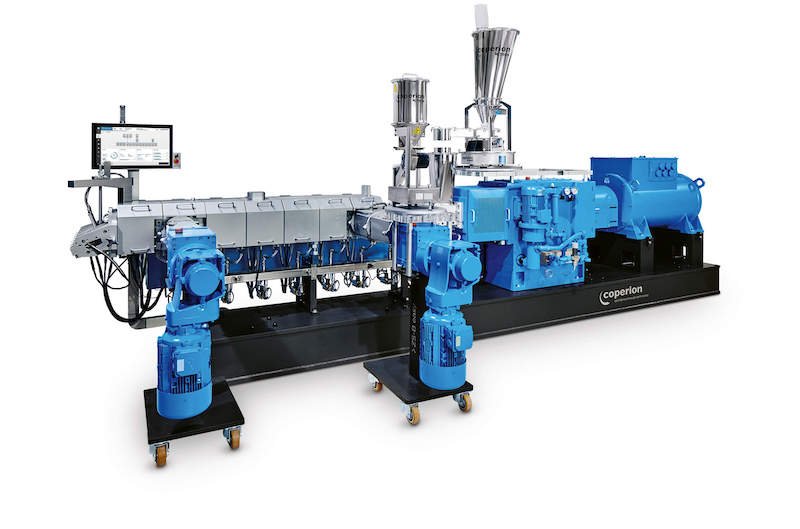

Coperion partnering in development of manufacturing technologies for graphite-polymer based bipolar plates

03.11.2021

Within the framework of a joint project with the University of Stuttgart’s Institute for Plastics Technology (IKT), Robert Bosch, and Matthews International/Saueressig, Coperion is working on the continued development of proton exchange membrane (PEM) fuel cells for efficient delivery of energy for everyday mobile use.

Coperion partnering in development of manufacturing technologies for graphite-polymer based bipolar plates

Bipolar plates as a core element of fuel cell stacks, and in particular their thermoplastic graphite compound-based implementations, are the focus of this work.

The extremely high fill levels pose challenges upon the process technology, the likes of which have not been seen before. As a partner in this project, Coperion is leveraging its expertise in developing the required machine-side solutions for manufacturing compounds.

Bipolar plates, made from graphite-polymer compounds, lend themselves to mobile applications due to their low weight. They combine properties such as electrical and thermal conductivity and gas non-permeability with higher mechanical capacity than pure graphite plates can achieve. Moreover, they withstand the effects of moisture and acid media at typical operating temperatures over longer periods of time than metal alloys.

Coperion has set the task of transferring its experience to the preparation of mixtures consisting of high amounts of graphite and low amounts of polymer, to lay the foundation for future upscaling.

Markus Fiedler, Process Technology, Team Leader of Chemical Applications at Coperion, said: “Our primary focus lies on two critical factors: The high proportions of graphite — in this project, filling levels far over 85 per cent by weight are targeted — at concurrently low bulk density requires special equipment to feed the mixtures into the extruder and increase the possible mass throughput. We want to optimally integrate this difficult material input into the process. Parallel to this, we are also optimising the incorporation of fillers into the polymer, to avoid creating agglomerates and degrading the polymer during compounding.”

For the base technology to improve intake behavior, Coperion uses patented Feed Enhancement Technology (FET). The intake section of the side feeder is equipped with a porous, gas-permeable wall. A vacuum is fitted on the outside, and part of the air contained in the mixture is sucked out. The bulk density thus increases and with it the material’s absorption capacity in the side feeder.

Coperion has also developed a process-optimised machine concept to homogenize the mixture, and is also developing an inline quality tool to detect process and product fluctuations.

The project is being promoted under registration number 03ETB028B of the German Federal Ministry for Economic Affairs and Energy using the acronym GrabaT (Graphite-based Bipolar plate Technologies).