Hot and cold reliably side by side thanks to sophisticated heat management

07.06.2023

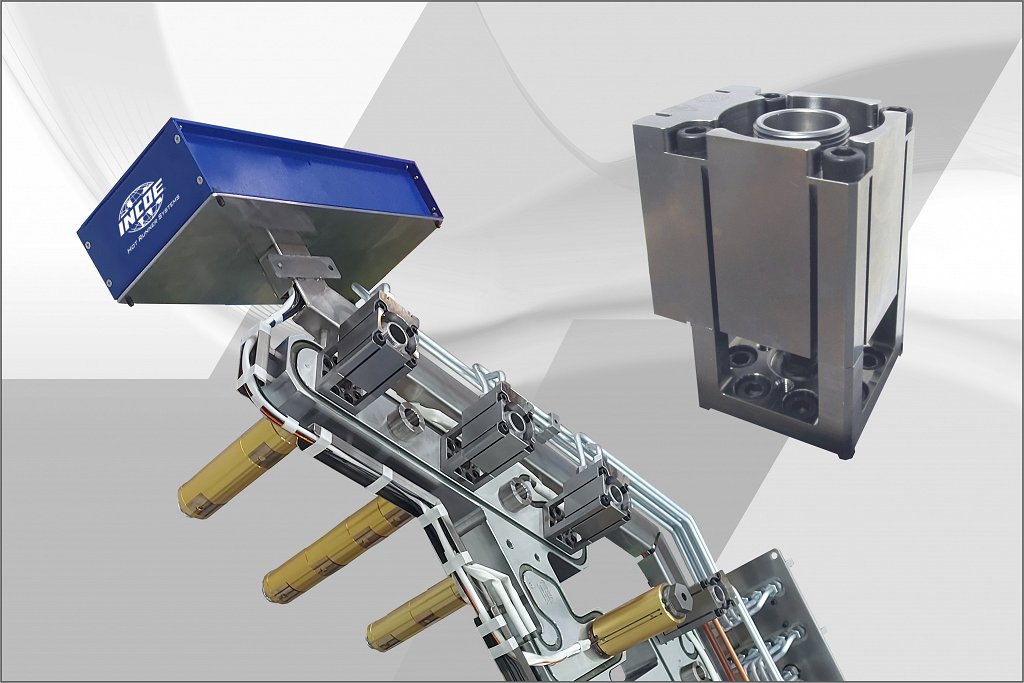

Compact valve gate cylinder HEM manages without cooling medium on the manifold

Compact and without cooling - the HEM type valve gate cylinder for ready-to-use and pre-assembled complete hot runner systems

Compact and without cooling - the HEM type valve gate cylinder for ready-to-use and pre-assembled complete hot runner systems

Ready-to-use and pre-assembled complete hot runner systems, where all components including the valve gate cylinders are mounted on the hot runner manifold ready to plug in, save a lot of effort and time during installation and maintenance. To protect the valve gate cylinders from the heat generated by the manifold during operation, an important part of the thermal separation is active liquid-based cooling. The compact hydraulic cylinder type HEM is now also available without cooling, which saves the associated effort and installation space in the mold. This is made possible by sophisticated heat management with the aid of minimized contact surfaces, reduced heat conduction cross-sections and corresponding heat dissipation. On the one hand, this protects the temperature-sensitive components of the cylinder and the hydraulic oil from overheating. On the other hand, it prevents excessive heat loss from the manifold, which needs its energy to keep the plastic melt at processing temperature. Sufficient thermal separation between the cylinder and the manifold is also ensured after the end of operation or during production interruptions.

The HEM valve gate cylinder is available in two sizes for the different series of INCOE's Direct-Flo™ hot runner program. Its very compact design saves installation space in the mold and enables small stitch dimensions. Without cooling, the HEM valve gate cylinder is designed to be installed at the rear of the mold plate and can be used for a wide variety of applications. Its thermal operating range is at a maximum melt temperature of 270 °C and a maximum mold temperature of 60 °C.